项目概述

This project showcases how I designed and delivered an end-to-end digital solution across IoT devices, station-level optimization, and service operations, helping industrial customers shift from reactive maintenance to predictable, measurable customer success.

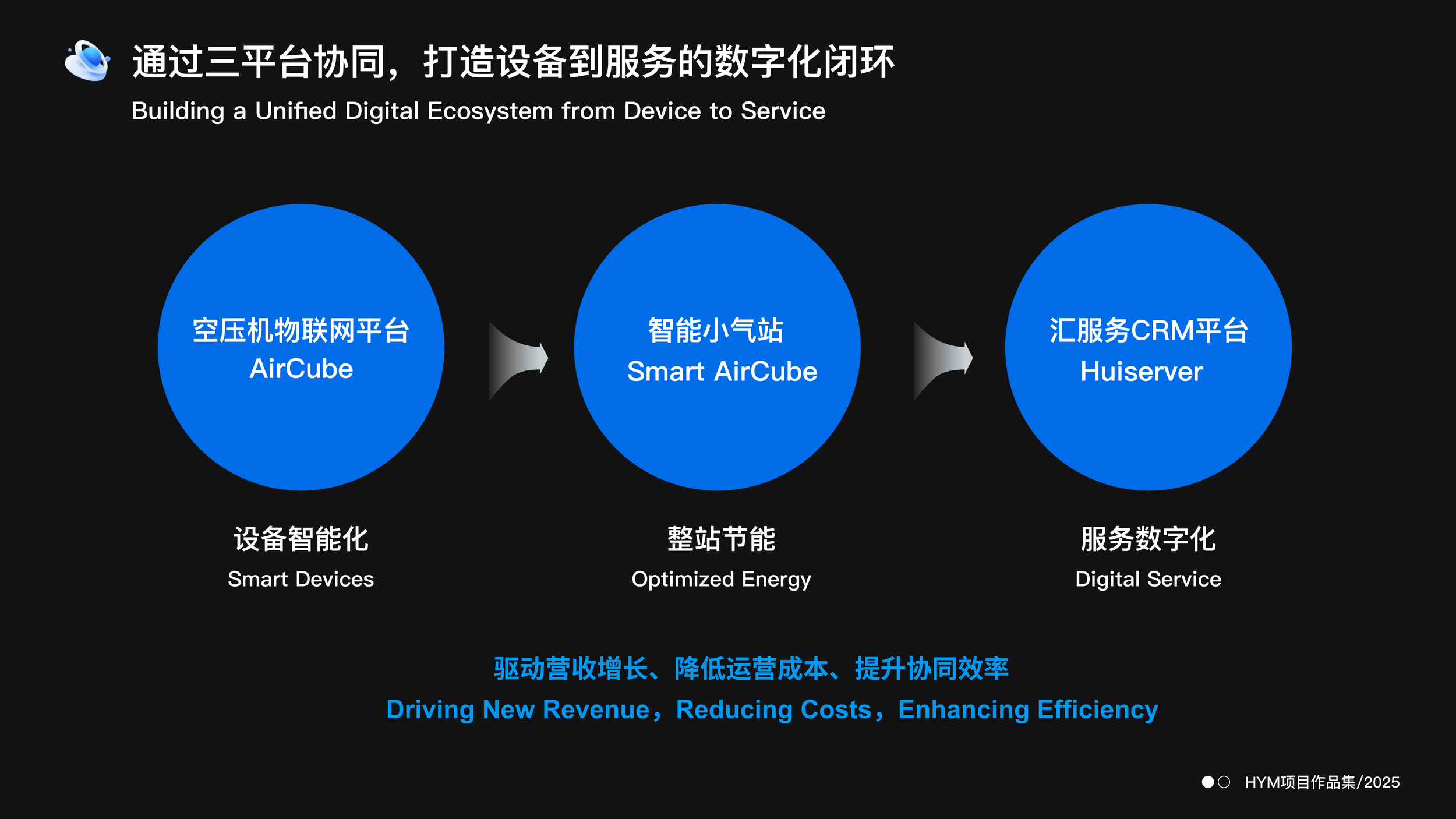

By integrating three platforms — Air Compressor IoT Platform, Smart Air Station SaaS, and Hui Service CRM — I enabled OEMs and service partners to improve operational efficiency, prove energy-saving value, and build scalable service-based revenue models.

本项目展示了我如何通过体验与解决方案设计,打通设备层、站房层与服务层,帮助工业客户从“被动维修”转型为可预测、可量化的客户成功模式。

通过整合空压机物联网平台、智能空压站 SaaS 与汇服务 CRM,支持 OEM 与服务商提升运营效率、验证节能价值,并构建可规模化的服务型收入模式。

Project Background 项目背景

From Product Delivery to Customer Achievement

从“交付产品” → “成就客户”

Industrial equipment companies are undergoing a fundamental shift — from selling machines to delivering ongoing services and outcomes.

However, many organizations face common challenges during this transition:

Device systems and service platforms are disconnected

Equipment operating status lacks transparency

Service response is slow, with unclear work order workflows

Maintenance relies heavily on manual processes, resulting in low efficiency

Limited service value creation makes renewals and repeat purchases difficult to sustain

To address these challenges, this project delivers an end-to-end solution that connects:

Device → Data → Service → Revenue → Continuous Optimization

工业设备企业正从“卖设备”转向“卖服务”,但当前普遍面临以下痛点:

设备与服务系统割裂

运行状态不透明

服务响应慢、工单链路不清晰

维保依赖人工、效率低

服务增值能力弱、续保和复购难维持

为解决这些挑战,该项目打造了一个覆盖端到端的解决方案:设备 → 数据 → 服务 → 收入 → 持续优化

Solution Overview (End-to-End Value Loop)

解决方案概述:端到端价值闭环

The solution consists of three interconnected platforms, forming a complete value loop across the customer lifecycle. I designed the overall approach as an End-to-End Value Loop, ensuring that customer value is continuously created, validated, and amplified over time.

End-to-End Value Loop

Device Connectivity

Devices are connected through the IoT platform, enabling real-time data acquisition.Station-Level Optimization

System-level energy optimization and intelligent control are implemented at the air station level.Service Execution

Service delivery and operations are managed through the CRM platform.Value Validation

Outcomes are visualized and quantified, making value transparent and credible.Scalable Growth

Proven results support renewals, upsell opportunities, and customer expansion.

Through this closed-loop approach, operational data is transformed into customer trust, measurable business value, and long-term retention.

该方案由三个平台构成,形成完整的价值闭环。我将整体方案设计为一个端到端价值闭环,确保客户价值在整个生命周期中被持续创造、验证和放大。

价值闭环路径:

设备上云:通过 IoT 平台完成设备接入

整站优化:在空压站层面实现系统级节能与控制

服务执行:通过 CRM 平台完成服务交付与管理

价值验证:将结果可视化、可量化

规模复制:支持续费、增购与客户扩展

该闭环将数据转化为信任、商业价值与客户长期留存。

My Role & Key Responsibilities 角色职责

Service Experience Designer(Interaction & Research)

My Responsibilities Included:

Leading customer research across operators, managers, and service teams

Translating customer success goals into product and service strategies

Designing cross-platform workflows and experience architecture

Defining measurable success metrics (efficiency, energy savings, adoption)

Supporting commercialization through value storytelling and metrics

I was not only designing solutions — I was responsible for making them successful in real customer environments.

体验设计师(交互设计 & 用户研究)

我的核心职责包括:

主导多角色用户调研(终端用户 / 管理者 / 服务团队)

将客户成功目标转化为产品与服务策略

设计跨平台体验架构与关键业务流程

定义可量化的成功指标(效率、节能、采用率)

支持商业化落地与价值表达

不仅设计方案,更对方案在真实客户场景中的成功负责。

Customer Success-Driven Need Discovery & Validation

客户成功导向的需求洞察与验证方法

Multi-Dimensional Customer Insight Framework

多维度客户洞察框架

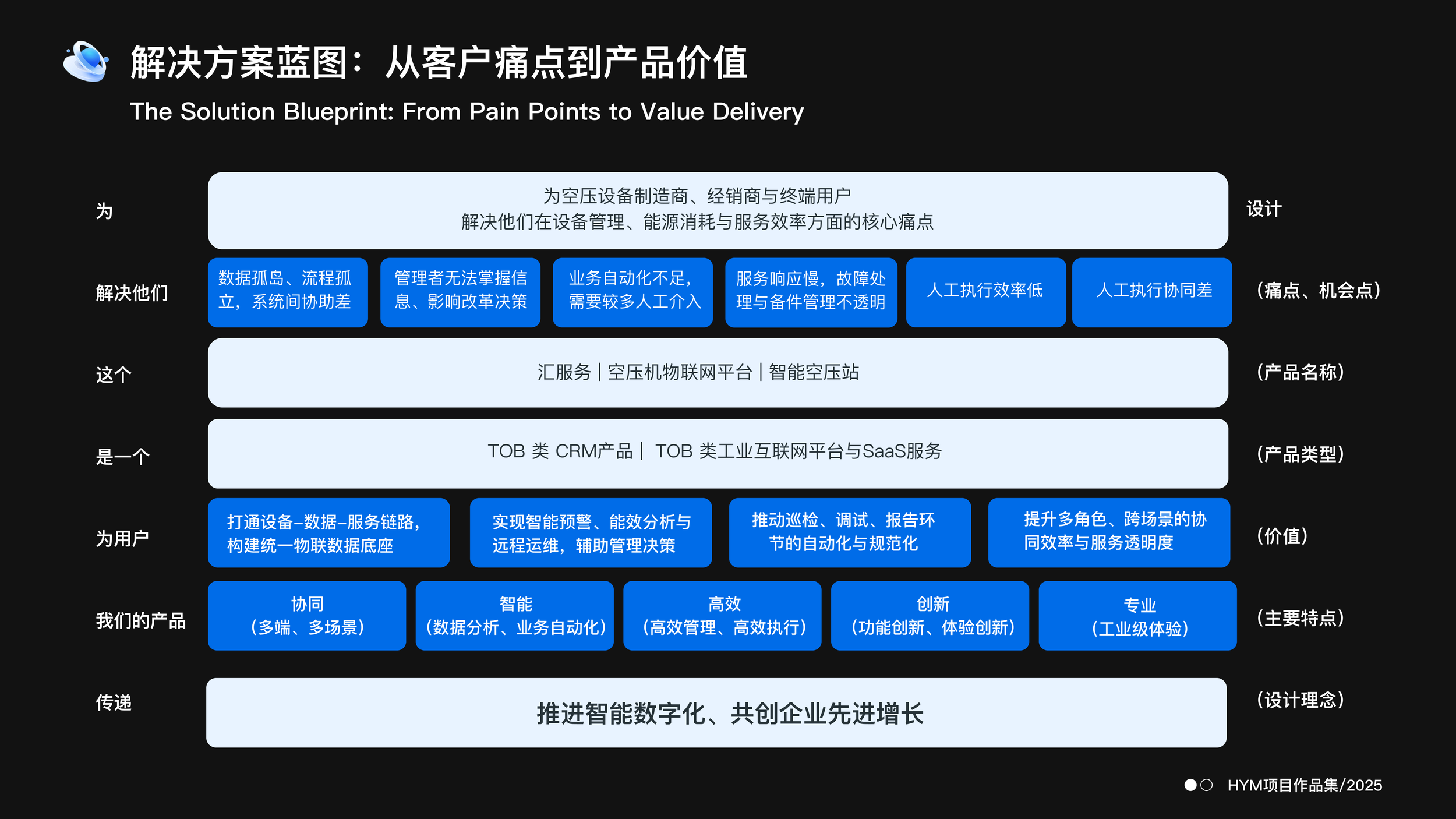

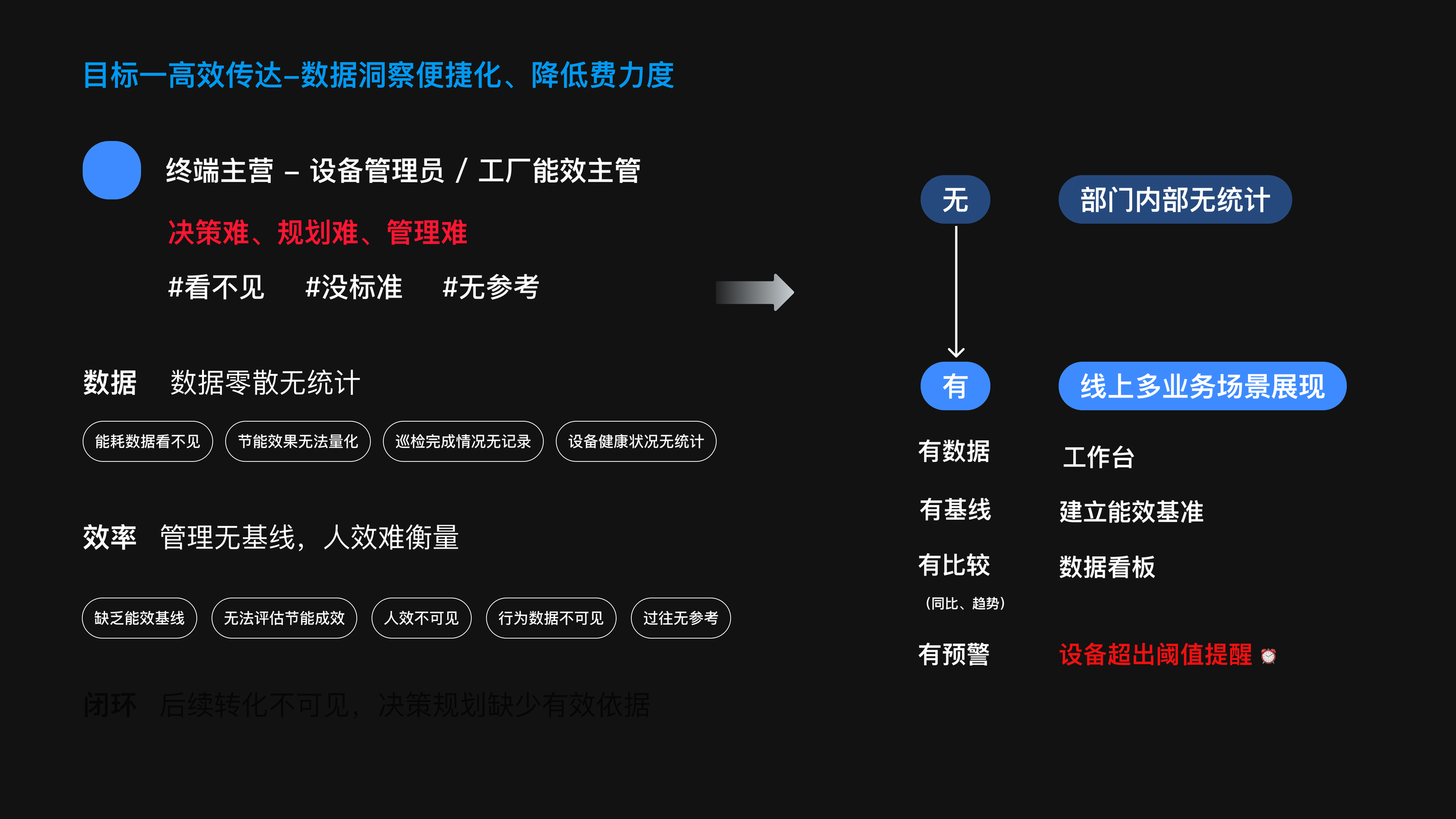

I adopted a five-layer analysis model: business scenario → user role → key task → pain point → success indicator. This ensured that design always serves the customer’s business objectives.

I validated the needs through:

Workshops with customers, sales, and service teams to define “success scenarios.”

Quantitative Pain Point Analysis: Narrowing down 30+ pain points to 8 core issues.

Prototype Testing & Data Simulation: Validating solution feasibility with interactive prototypes and historical data.

Kano Model Analysis: Categorizing features into Must-be, Performance, and Delighter needs to prioritize the roadmap.

摒弃传统的功能清单式需求收集,我转而采用业务场景→用户角色→关键任务→痛点→成功指标的五层分析模型,确保设计始终服务于客户业务目标。

我通过以下方法系统验证需求真实性、优先级与价值潜力:

工作坊共创:与客户、销售、服务团队共同定义“成功场景”

痛点量化分析:30+痛点中聚焦8个高影响、高频率的核心问题

原型测试 + 数据模拟:用可交互原型验证方案可行性,并用历史数据模拟价值效果

Kano模型分析:区分基本型、期望型与魅力型需求,规划体验演进路径

Platform 01: Smart Air Station Solution

平台01:智能空压站解决方案

Turning Energy Optimization into Provable Customer Value

整站节能 = 客户“看得见的价值”

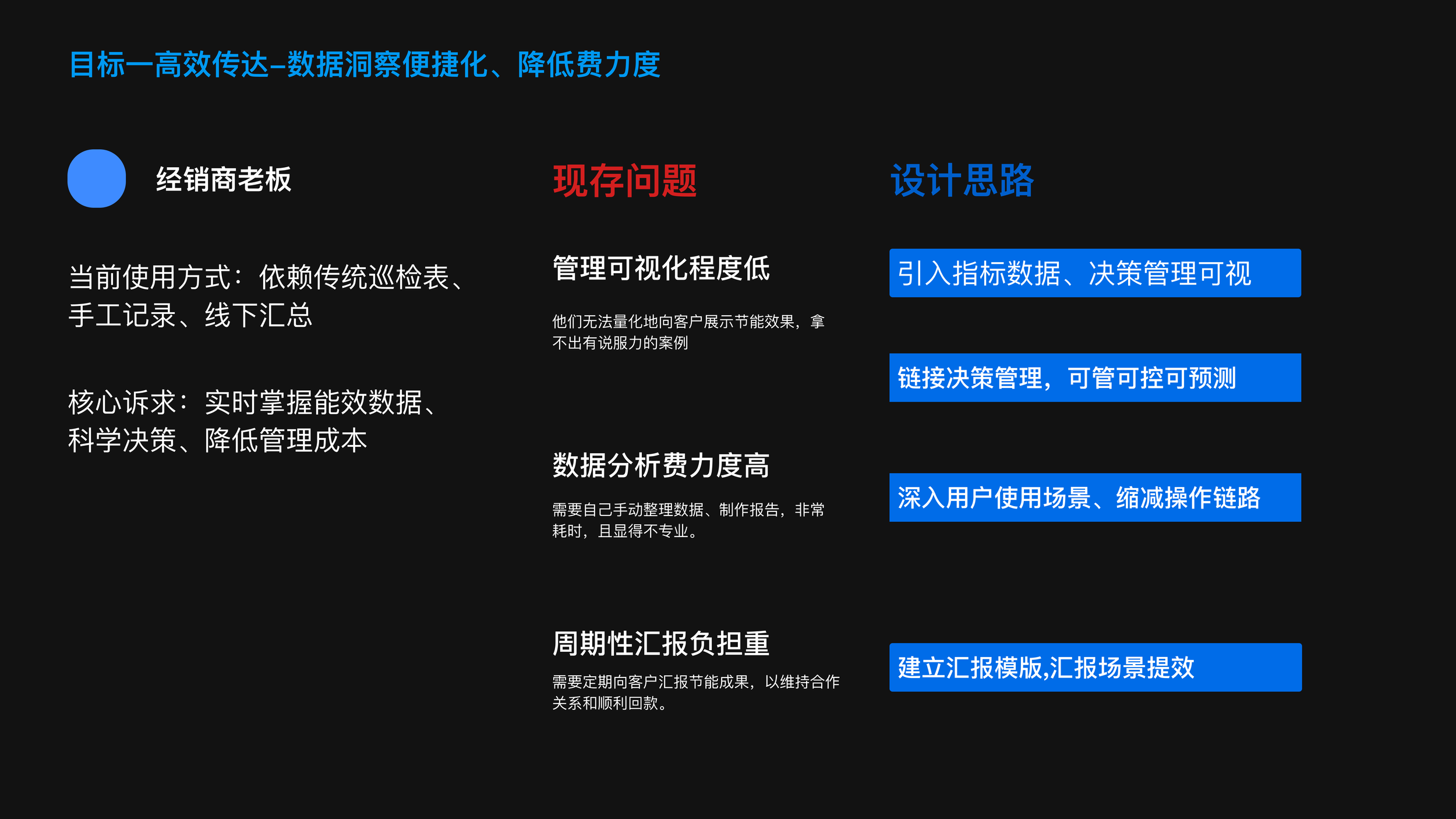

The Smart Air Station SaaS focuses on system-level outcomes, helping customers move from fragmented device operations to measurable energy and cost performance.

As the service and experience design lead, I played a key role in translating complex operational data into clear, decision-ready value narratives for both customers and dealers.

智能空压站 SaaS 聚焦于系统级成果,帮助客户从割裂的设备管理模式,升级为可量化、可验证的节能与成本优化结果。作为服务与体验设计负责人,我重点参与了将复杂的运行数据转化为管理层与业务方都能理解和信任的价值表达方式,识别客户成功痛点。

My Contribution to the Solution

我的解决方案贡献

From an experience and service design perspective, I ensured that energy-saving value is perceivable, verifiable, and reusable:

Centralized Web Control Dashboard

Designed a unified view of energy consumption, system health, and alerts to support daily operations, maintenance workflows, and management decision-making.

Mobile Experience Delivery

Streamlined user journeys for multi-role mobile scenarios, enabling real-time data access, alarm handling, and remote start/stop operations to support convenient off-site and on-site management.

Experience Translation of Group Control Algorithms

Worked closely with algorithm and R&D teams to translate complex control logic into system behaviors that users can understand, trust, and operate with confidence.

Intelligent Energy-Saving Report Design

Built automated reporting workflows that transform raw operational data into clear, structured energy-saving insights for internal reporting and customer communication.

我从体验与服务设计层面,确保节能价值可感知、可验证、可复用:

集中式 Web 管控大屏

设计统一的能耗、系统健康度与告警视图,支持日常运维与管理决策。移动端体验落地

简化操作路径适配多角色移动场景,支持实时数据查看、告警处理、远程启停等功能,满足外出 / 现场作业的便捷管控需求。

群控算法的体验表达

与算法与研发团队协作,将复杂的控制逻辑转化为用户可理解、可操作的系统行为。智能节能报告设计

构建自动化报告流程,将原始数据转化为可用于内部汇报与客户沟通的节能成果说明。

Customer Value

Improved Operational Efficiency: Equipment status visualization combined with mobile control significantly accelerated fault response and issue diagnosis.

Quantifiable Energy Savings: Data-driven reports made energy reduction outcomes visible, measurable, and verifiable.

Enhanced Multi-Device Coordination: Enabled intelligent, coordinated scheduling across multiple compressors, avoiding single-unit overload or inefficient operation and improving overall system stability.

More Effective Management Decision-Making: Provided management with clear visibility into station operations and cost data, supporting optimized resource allocation.

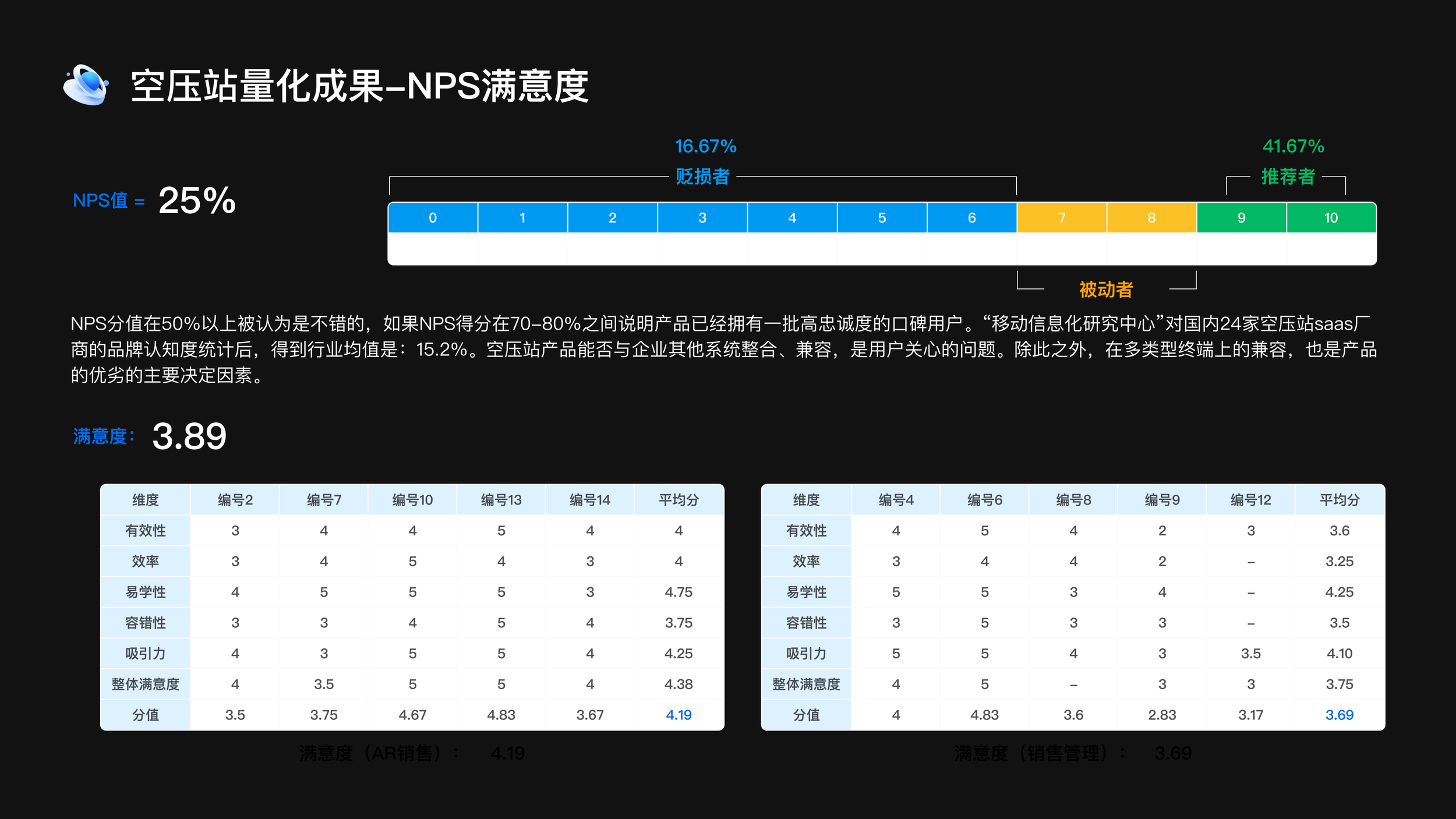

The air compressor station project has an NPS of 25% (higher than the industry average of 15.2%), with 41.67% promoters and 16.67% detractors; its overall satisfaction score is 3.89, while the satisfaction scores for AR sales and sales management are 4.19 and 3.69 respectively.

实现的客户价值

运维效率提升:设备状态可视化 + 移动化管控,故障响应与问题定位速度显著加快

节能效果可量化:通过数据报告让能耗降低成果 “可视化、可验证”

多设备联控增效:实现空压站多台设备智能协同调度,避免单机过载或低效运行,提升整体机组运行稳定性

管理决策提效:管理层获得清晰的空压站运行 / 成本数据,支撑资源优化配置

空压站项目 NPS 值为 25%(高于行业均值 15.2%),其中推荐者占 41.67%、贬损者占 16.67%,整体满意度 3.89 分,AR 销售端与销售管理端满意度分别达 4.19 分、3.69 分。

Platform 02: Air Compressor IoT Platform

平台02:空压机物联网平台

The Air Compressor IoT Platform targets device-level management scenarios for single or multiple compressors, focusing on independent monitoring and on-site operations for standalone or distributed equipment.

Customer Success Challenges Addressed

Lack of Cross-Platform Coordination: Disconnected data between Web and mobile systems prevented real-time collaboration between on-site operations and back-office management.

High Manual Dependency: Inspections and status tracking relied heavily on offline processes, leading to delays and information gaps.

High Onboarding and Maintenance Costs: Device connectivity required specialized configuration, and troubleshooting depended largely on individual experience.

My Contribution to the Solution

Web-Based Centralized Control Experience: Designed a one-stop Web control center integrating device fleet status, energy data, and alert dashboards to enable real-time, centralized monitoring of multiple compressors.

Mobile App for On-Site Operations: Delivered an App experience tailored to field work, supporting QR-based device binding, real-time data access, alert notifications with on-site feedback, and remote start/stop—allowing technicians to complete end-to-end tasks without relying on a PC.

Seamless Cross-Platform Data Synchronization: Unified data models and interaction logic across Web and App, ensuring real-time synchronization of device status, alerts, and operation logs, and enabling smooth collaboration between centralized management and mobile field operations.

空压机物联网平台面向空压机设备级单台 / 多台管理场景,聚焦单台或分散空压机的独立监控与现场作业。

需解决的客户痛点

多端协同缺失:传统管理中 Web 端与移动端数据割裂,现场运维与后台管控无法实时联动

人工依赖度高:设备巡检、状态跟踪依赖线下作业,信息传递滞后且易遗漏

接入与运维成本高:设备联网需专业配置,后期故障排查依赖人工经验

我的解决方案贡献

Web 端全局管控体验设计

构建 Web 端一站式中控界面:整合空压机设备集群状态、能耗数据、预警看板等模块,支持多设备的集中监控,支撑空压机实时监控

App 端移动运维体验落地

适配现场作业场景的 App 端设计:实现设备扫码快速绑定、实时数据查看、告警推送与现场反馈、远程启停控制等功能,让巡检员 / 维保人员脱离 PC 端即可完成全流程作业,打通 “后台 - 现场” 的协同链路

跨端数据协同体验打通

统一 Web 与 App 端的数据标准与交互逻辑,确保设备状态、告警信息、操作记录等数据实时同步,实现 “后台全局管控 + 现场移动作业” 的无缝衔接

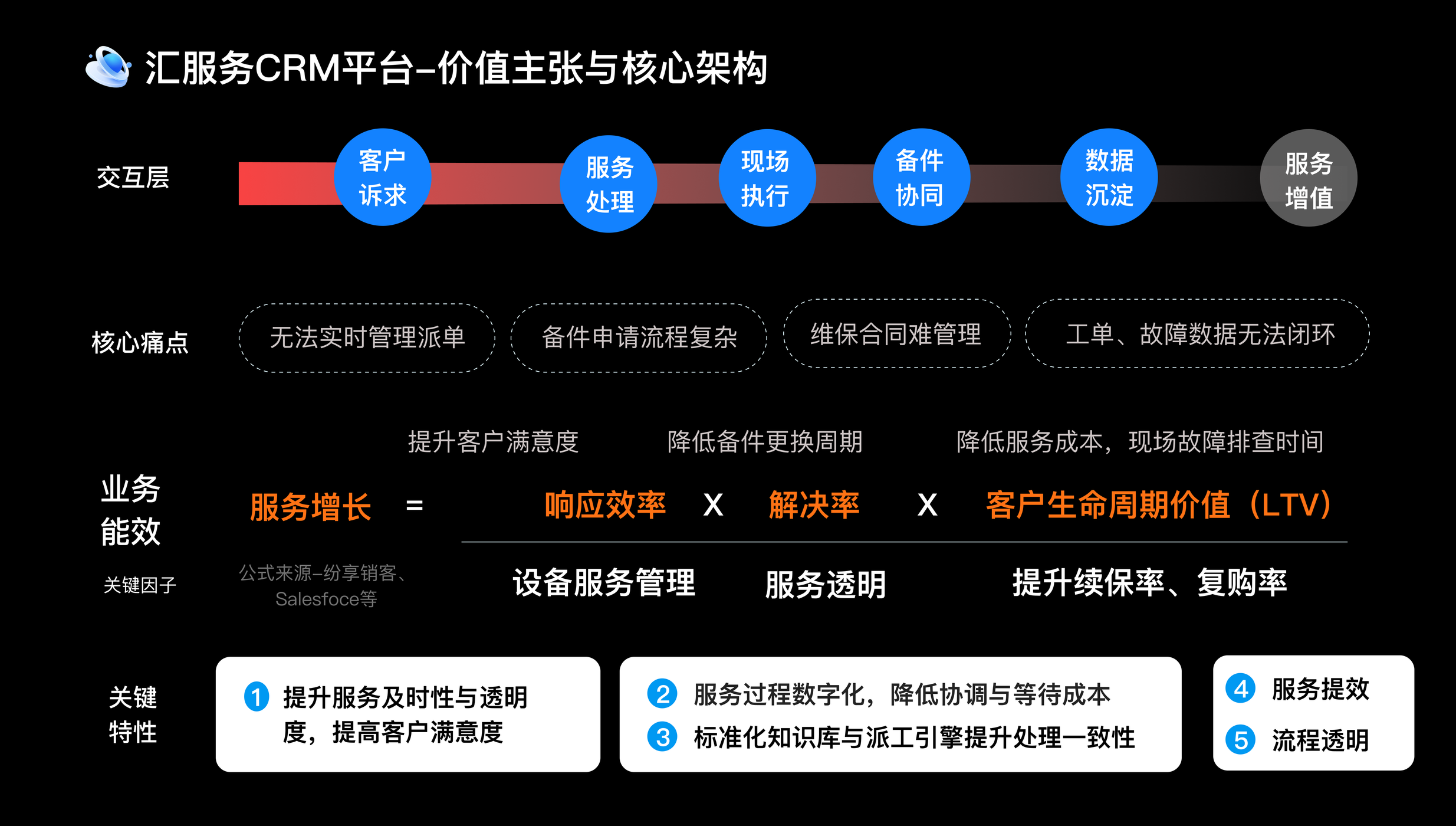

Platform 03: Hui Service CRM Solution

平台03:汇服务 CRM 解决方案

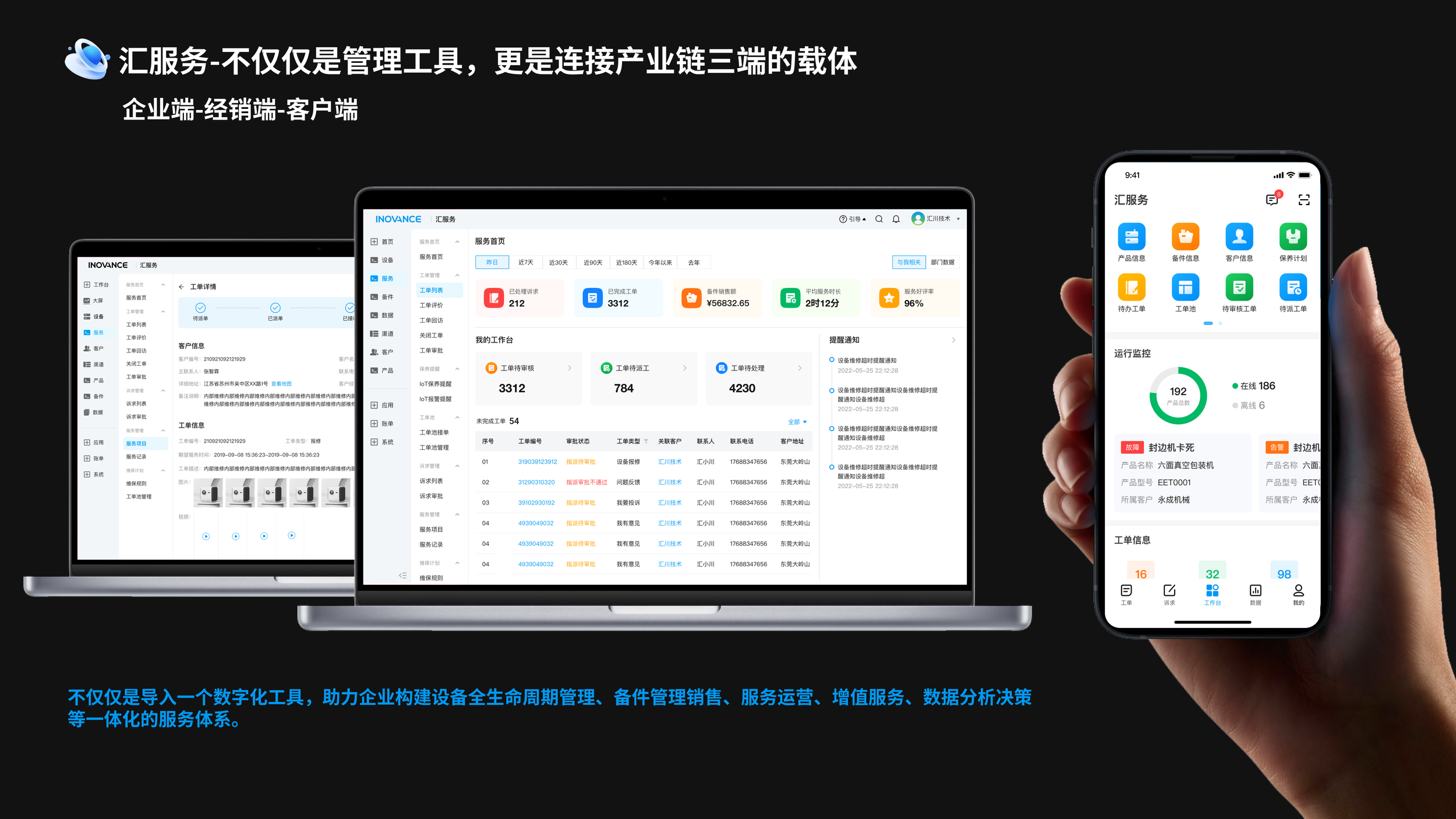

The Hui Service CRM Platform acts as a carrier connecting enterprises, distributors, and clients, building an integrated service system covering the entire lifecycle of equipment, parts, and services across Web and App terminals.

汇服务 CRM 平台是连接企业端 - 经销端 - 客户端的载体,通过 Web 与 App 端构建覆盖设备、备件、服务全生命周期的一体化服务体系。

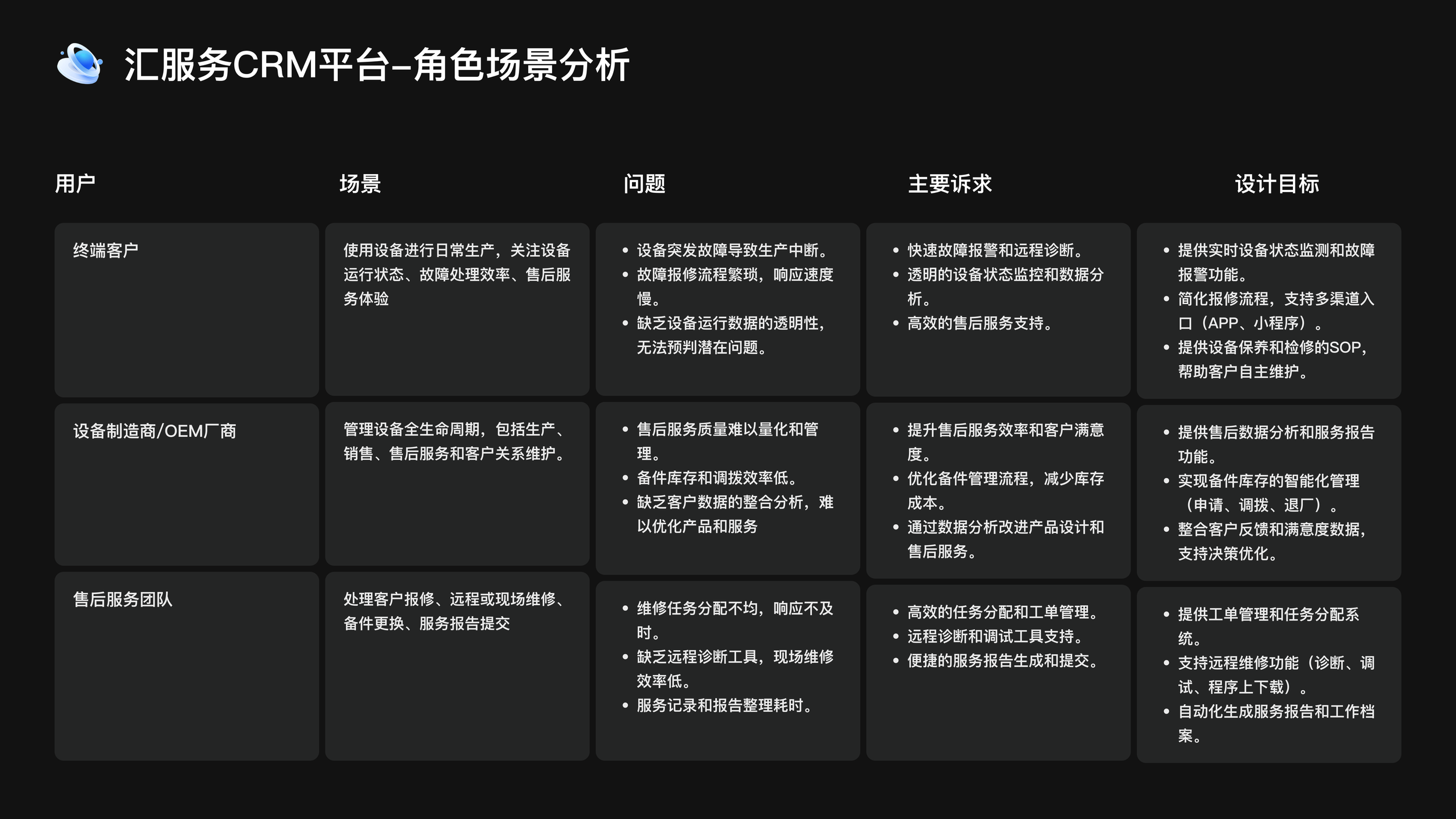

Customer Success Challenges Addressed

Fragmented Service Workflow: Disconnected data across enterprises, distributors, and customers; offline work orders were manual and slow to respond.

Lack of Service Transparency: No real-time visibility into service progress or spare-part flows; issue resolution relied heavily on individual experience.

Reactive Service Model: No predictive maintenance, inefficient spare-part management, and limited conversion of service value into revenue.

解决的客户痛点

服务链路割裂:企业、经销商、客户间数据不通,线下工单操作繁琐、响应滞后

现场服务不透明:服务进度、备件流转无实时记录,故障处理依赖人工经验

被动服务模式:设备维护无预判,备件管理低效,服务价值无法转化为营收

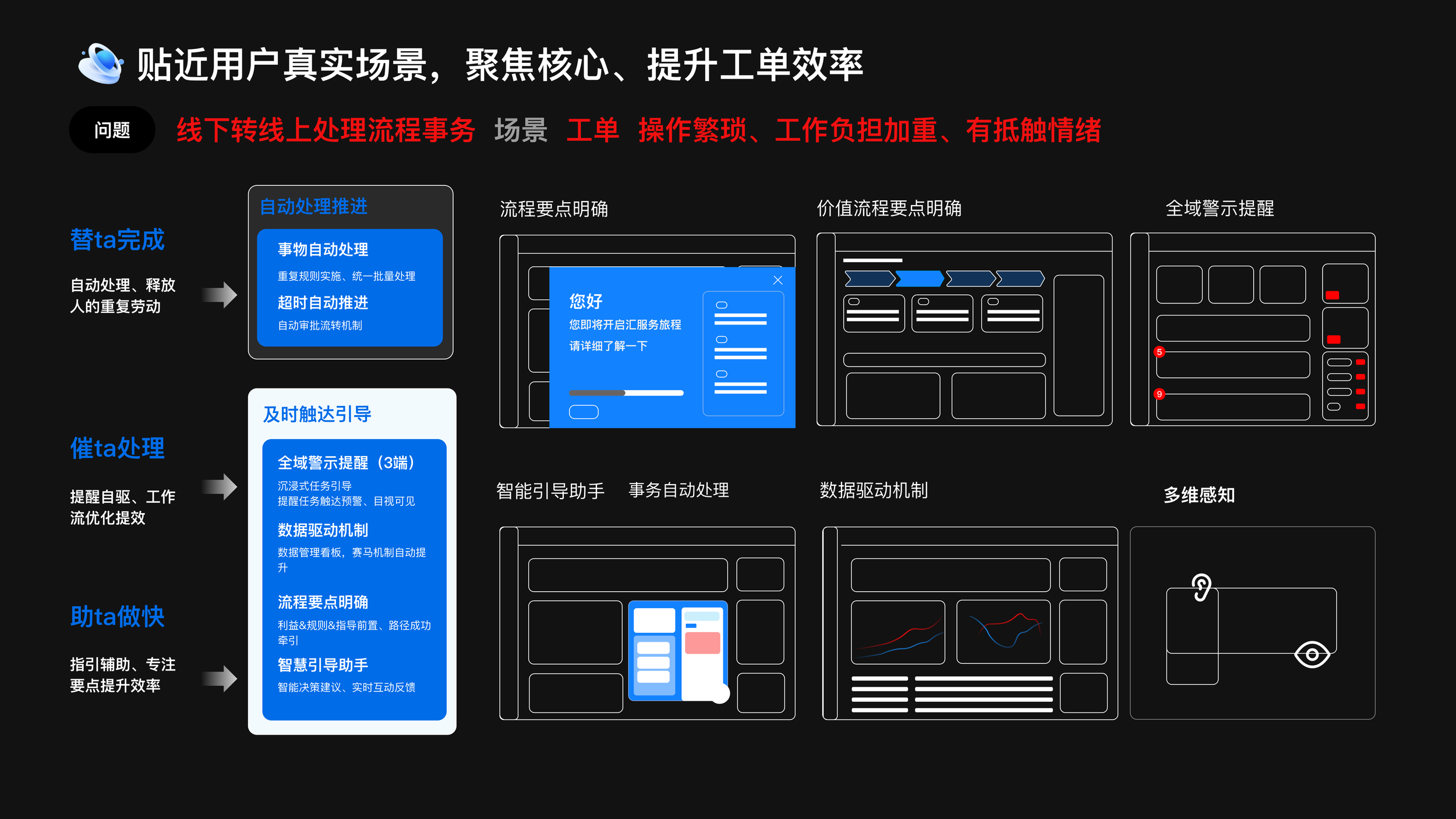

My Contribution to the Solution

End-to-End Service Experience Design: Connected the full chain from customer request to service execution, spare-part coordination, and data accumulation. Designed multi-channel service entry points (phone, IoT, WeChat), automated dispatching, and progress tracking to digitize and make service processes transparent.

Cross-Role Experience Enablement: Delivered role-specific capabilities—device monitoring and alarms for customers, intelligent spare-part management and analytics for manufacturers, and remote diagnostics with automated work orders for service teams.

Efficiency-Driven Experience Delivery: Implemented “automation + intelligent guidance” mechanisms, including auto-advancing workflows, contextual alerts, and process guidance, while enabling online spare-part application, verification, and tracking to reduce cycle times.

我的解决方案贡献

全链路服务体验设计

打通 “客户诉求 - 服务处理 - 现场执行 - 备件协同 - 数据沉淀” 链路:设计多渠道服务接入入口(电话 / IoT / 微信)、自动派单与进度追踪功能,实现服务流程线上化、透明化跨角色场景适配

针对终端客户、设备制造商、售后团队等角色设计差异化功能:为客户提供设备状态监控 / 故障报警,为制造商提供备件智能管理 / 数据决策报表,为售后团队提供远程诊断 / 工单自动化工具效率提效体验落地

设计 “自动处理 + 智能引导” 机制:通过事务自动推进、全场景预警提醒、流程要点指引,降低人工重复劳动;同时实现备件在线申请 / 核销 / 追踪,缩短流转周期

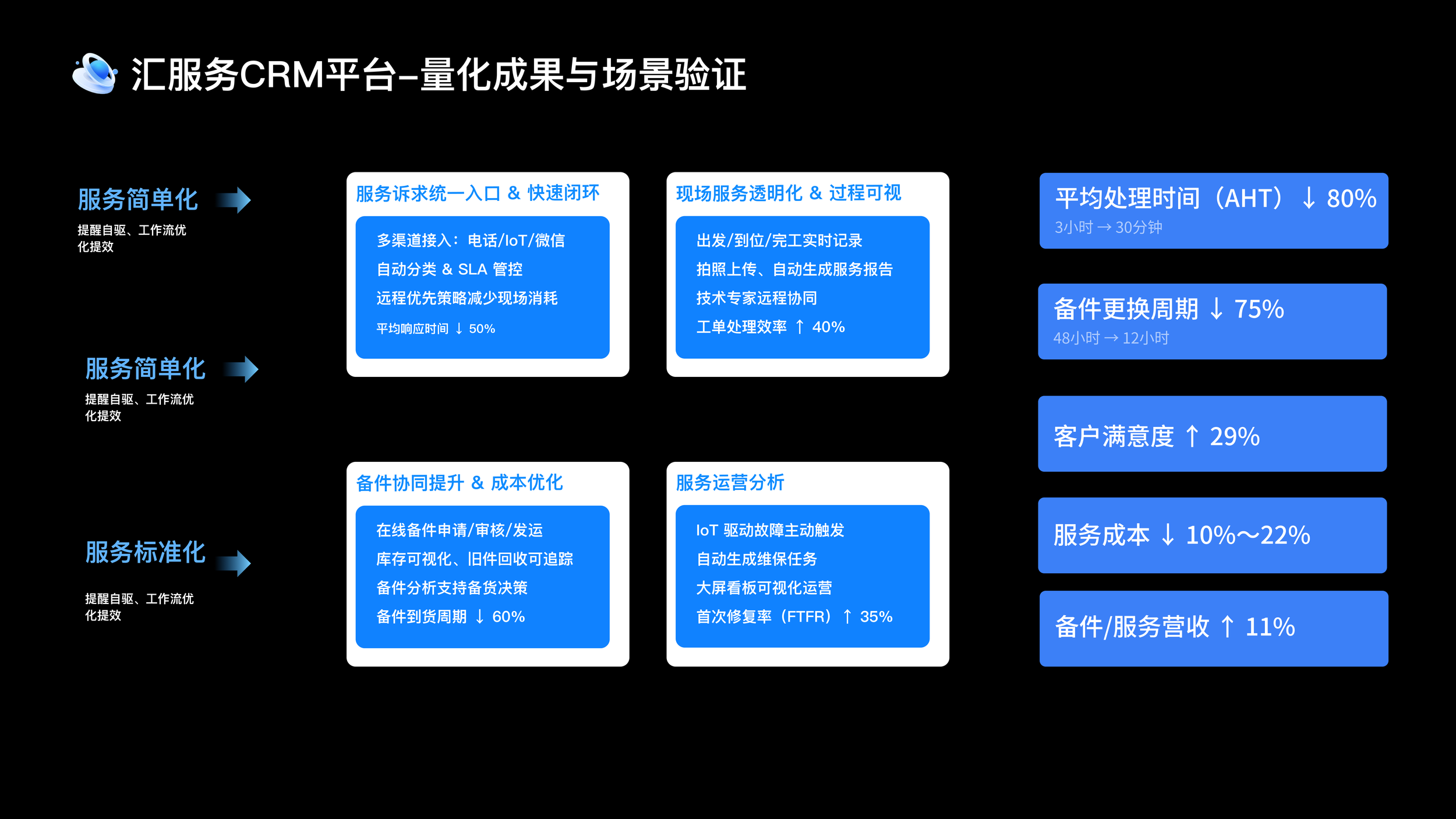

Results

Service Efficiency Gains: Average handling time reduced by 80% (from 3 hours to 30 minutes); work order efficiency improved by 40%.

Cost and Experience Optimization: Spare-part replacement cycles shortened by 75%, customer satisfaction increased by 29%, and service costs reduced by 10%–22%.

Business Value Creation: Spare-part and service revenue increased by 11%, enabling a shift from reactive service to proactive, value-added service.

成果

服务效率提升:平均处理时间缩短 80%(3 小时→30 分钟),工单处理效率提升 40%

成本与体验优化:备件更换周期缩短 75%,客户满意度提升 29%,服务成本降低 10%-22%

商业价值转化:备件 / 服务营收增长 11%,实现从被动服务到主动增值的模式升级

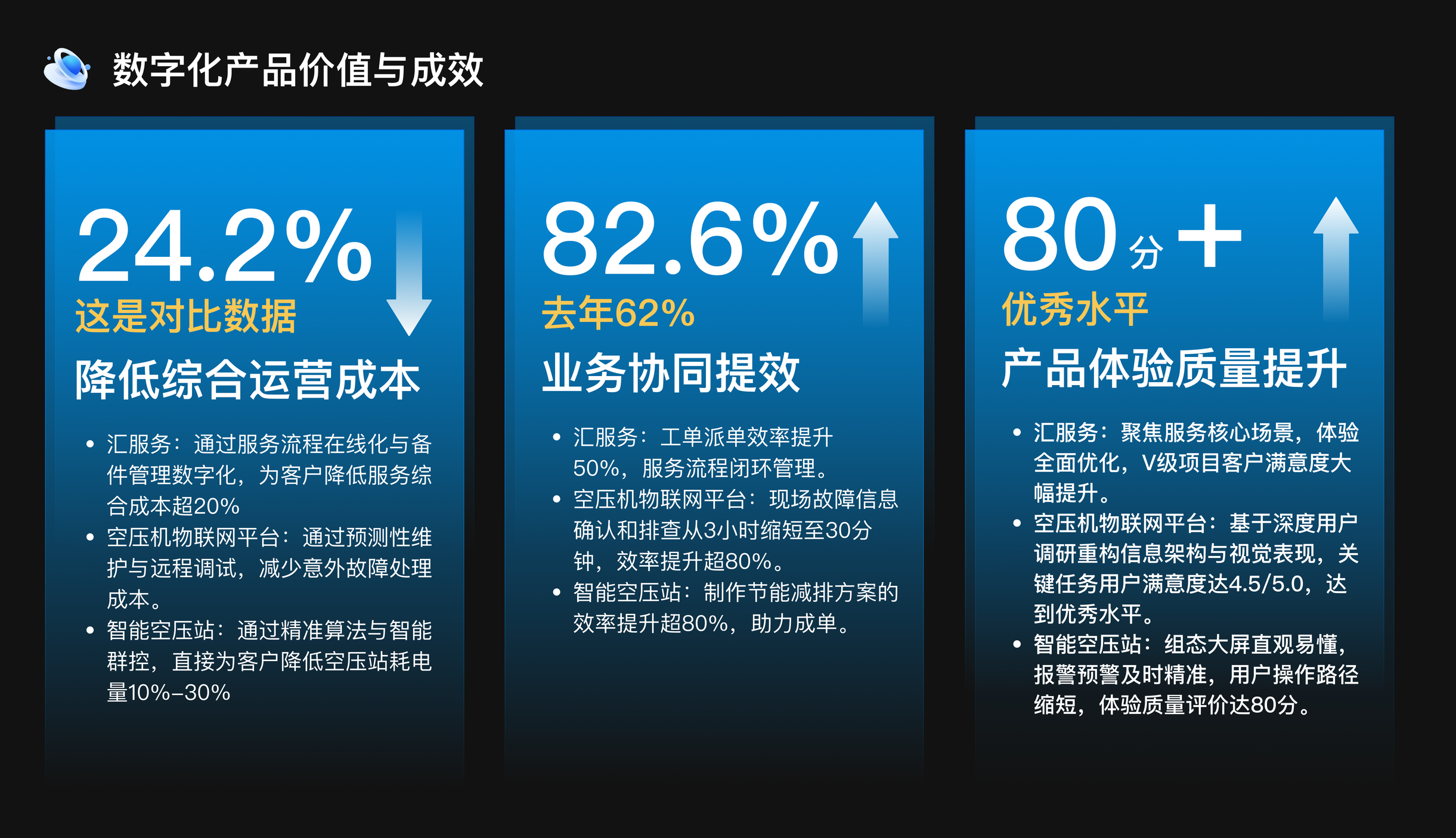

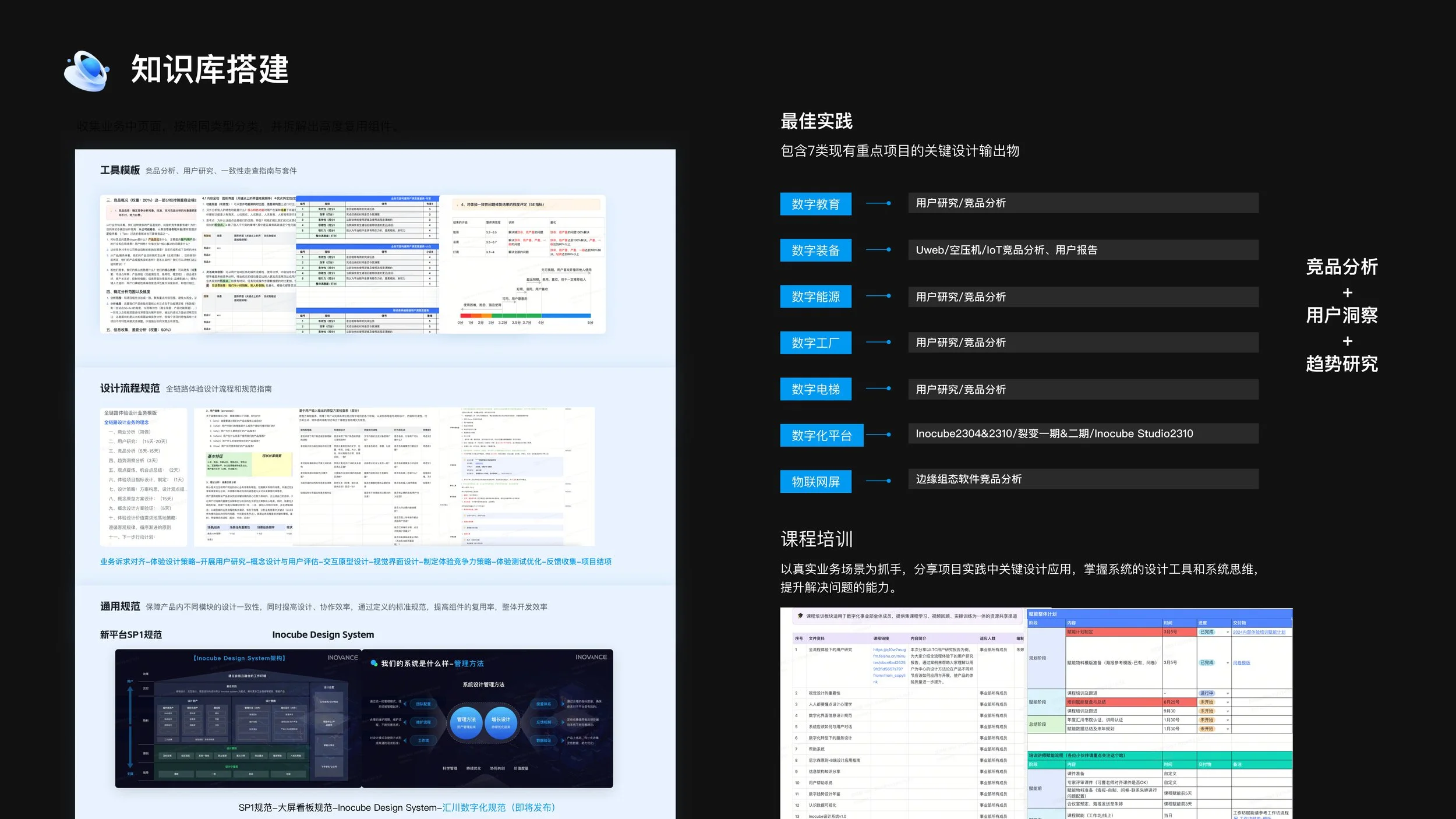

My Work & Outcomes

I led the experience and value integration across three interconnected platforms — Hui Service CRM, Air Compressor IoT, and Smart Air Station — while building a reusable knowledge base to support long-term scalability.

At the platform level, I translated complex operational data and service processes into clear, quantifiable value across cost, efficiency, and experience, ensuring that outcomes were visible, credible, and decision-ready for different stakeholders.

At the system level, I established a structured knowledge base by creating toolkits, templates, and best-practice patterns, enabling experience standardization, team empowerment, and faster iteration across projects.

Key Outcomes

Platform Impact

24.2% reduction in comprehensive operational cost

82.6% improvement in cross-business collaboration efficiency

Product experience quality rated 80+, with measurable satisfaction and adoption gains

Capability & System Impact

Higher design efficiency and experience reusability

Stronger cross-team design consistency

A sustainable experience iteration mechanism supporting future platform evolution

This project demonstrates how experience design can move beyond interface optimization to become a strategic enabler of customer success, operational efficiency, and scalable growth.

我的工作与成果

我作为体验与服务设计负责人,统筹了 汇服务 CRM、空压机物联网、智能空压站 三大平台的体验与价值整合,并搭建了支撑长期演进的设计与知识体系。

在平台层面,我将复杂的设备数据与服务流程,转化为在成本、效率与体验维度可量化、可感知、可决策的客户价值,帮助不同角色清晰理解数字化投入所带来的实际收益。

综合运营成本降低 24.2%

业务协同效率提升至 82.6%

产品体验质量稳定在 80 分以上,用户满意度与使用意愿显著提升

在体系层面,我通过构建工具模板、方法框架与最佳实践库,推动设计标准化与能力沉淀,实现团队赋能与项目复用。

设计效率与经验复用性显著提升

跨团队体验一致性增强

构建了支持持续演进的体验迭代与能力成长机制

该项目不仅验证了体验设计在工业场景中的落地价值,也证明了其在客户成功、业务效率与规模化增长中的战略作用。